The Norfolk Canneries company was set up by Frank Corbett in October 1931, the years of The Great Depression, following the Wall Street Crash. Albert Duncan joined in 1934 and effectively took over the operation.

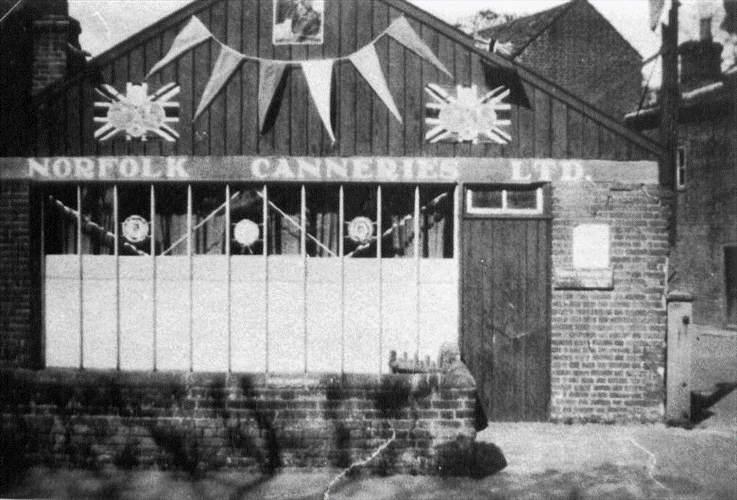

Norfolk Canneries first premises at the corner formed by New Road and Pound Road and known as Park Hall.

Mr Duncan was keen to reinvigorate trade in the local area which, particularly at that time was a prolific growing area for fruit and vegetables, especially strawberries, when in season. Each day “Duncan” trucks went out into the countryside to collect the fruit and vegetables, both from farms and decent sized allotments.

Albert Duncan was both a good employer and an astute businessman and by 1938 had built up financial reserves to such a level that he was able to buy both the Park Hall site and the land for the Norwich Road factory, formerly Cornish & Gaymer’s building yard.

A memory from this time is of a school boy turning down Pound Lane on his way to Manor Road School, who noticed a strong smell of strawberry juice. “This should have gone down the Company drain, but this was blocked and the juice overflowed into the gutter! Lovely!!”

In the early 1940s the Norwich Road site was developed and Park Hall closed. These were, of course, the war years, when demand for canned goods, both for home and forces overseas shot up.

Investment came in 1951, when HP Foods bought a majority shareholding in the Company, but did not at that stage involve themselves in the day to day running. They were happy as long as the baked beans flowed. They did, in 1955, choose North Walsham as the main production site for the beans (already branded HP Baked Beans. All other lines were still branded “Duncan”). The impact of the new machinery is shown in that before, the lines canned 64 cans per minute, afterwards it was 450 cans per minute.

In 1972 Smedleys of Wisbech merged with HP and the group title became Smedley H P.

By 1979 the overall ownership had passed to Imperial Tobacco Ltd and the group consisted of 11 factories. But by then the canning industry was suffering from intense competition from frozen food sales. It became clear to the people at North Walsham that changes were afoot, which caused plenty of worry among the employees at all levels. However despite that the North Walsham factory survived. In several instances innovations made at North Walsham, both in accountancy and engineering were by request installed throughout the factories of the group.

After 1980 the factory dropped the remaining fruit and vegetables but carried on with baked beans, spaghetti and soups. This arrangement lasted until 1996 but the operation ran down and closed in 2002.

Duncan canned products featured in a 1954 advertising film, ‘The moment of perfection’ (Courtesy of East Anglian Film archive)

Working at the Canneries

The peak labour force of around 500 was probably in the summers, during and immediately after the Second World War, when the full range of fruit and veg was being canned – plus the demand from the Forces.

Later, the basic figure was 250, rising to 300 in the summer whilst fruit and vegetables were being canned. There were 30 in Maintenance, 15 in the Office and 10 in the Laboratory. Of the balance, about 150 were literally ‘maids of all work’.

Most of their jobs were routine, boring even, but some needed a high level of concentration. Typical was the task of checking for substandard beans on the moving belt. One worker, pregnant at the time, felt giddy, and had to be removed to another job.

It was mostly reckoned to be a reasonably happy place to work. Levels of pay were marginally better than others in the area. For most women, the other option was in the town’s shops. Apart from the small pay differential, the great bonus was Saturdays – at least in the afternoons they were free. Most married women were working to supplement their men’s often agricultural level wages.

Overtime was an occasional perk, sometimes in an odd situation. One lady, who lived nearby on the Estate, who was working 8 – 5, was asked to go home and have a bite to eat, then come back and join the 6 – 10 shift, where someone had called off. The 6 – 10 shift was for married women whose husbands then looked after the children.

Canning Calendar

Apart from fruit and vegetables, from quite early on the canning of baked beans was important all year. In the off season the factory also canned processed peas, spaghetti and soups. The canning calendar for the fresh produce shows:-

- New potatoes (Jersey Royals) April, May

- Carrots June – December

- Broad beans, runner beans, peas July, August

- Strawberries, raspberries July, August

- Blackberries September

- Rhubarb May, June

Oddities

Seen from a 21st century perspective, some of the products that were canned appear a trifle strange. Among these were tinned chips, (soggy is the first word to come to mind). After being chipped they were soaked in a solution of calcium compound, dried, part fried then canned. Water was first canned during the war but well after that a batch was produced for the Australian Armed Forces, which was packed in wooden crates (obviously before era of plastic bottles).

An innovation from Smedleys was a system to produce sausage rolls, which they could not get to work. Although the North Walsham team eventually succeeded with these, the product didn’t catch on